Description

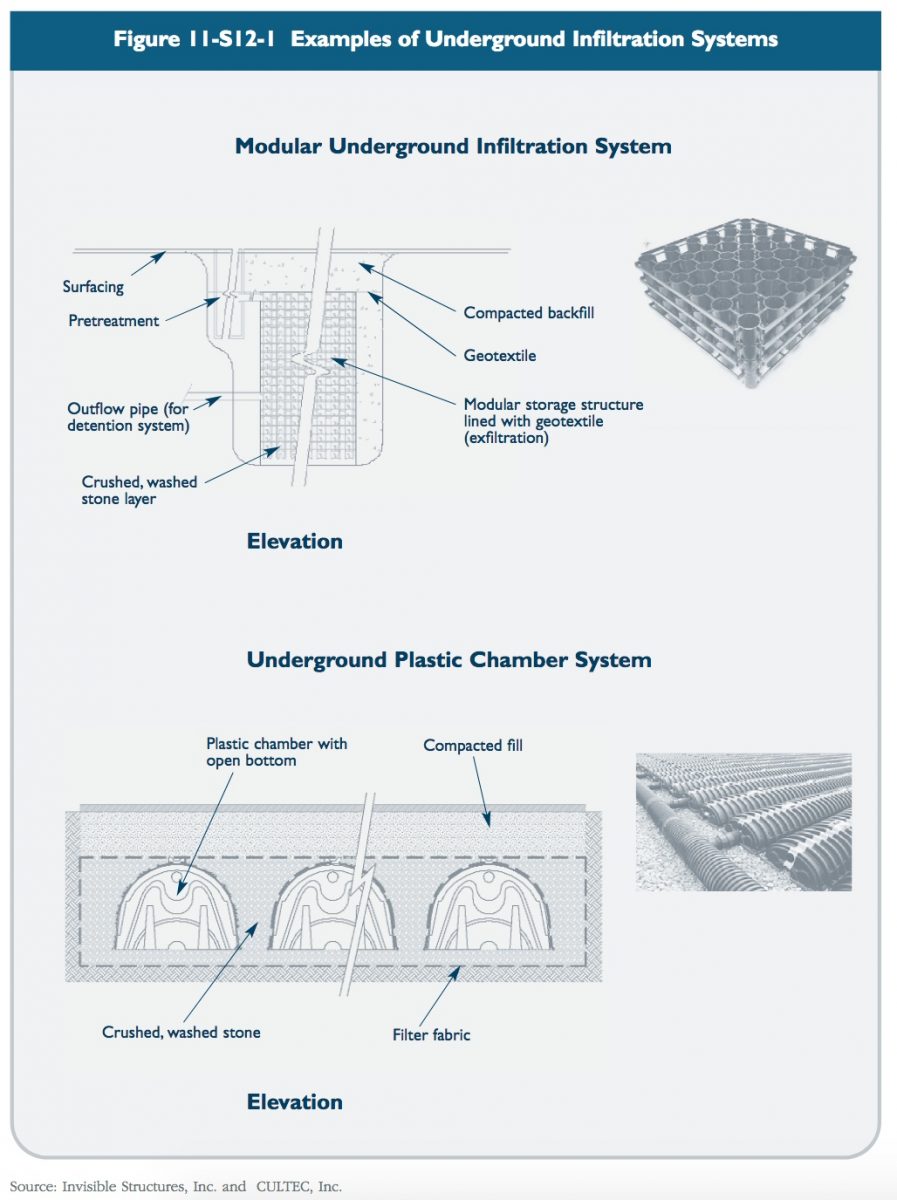

A number of underground infiltration structures, including premanufactured pipes, vaults, and modular structures, have been developed as alternatives to infiltration trenches and basins for space-limited sites and stormwater retrofit applications. Similar to traditional infiltration trenches and basins, these systems are designed to capture, temporarily store, and infiltrate the water quality volume over several days. These devices are typically designed as off-line systems, but can also be used to retain and infiltrate larger runoff volumes. Performance of underground infiltration structures varies by manufacturer and system design. These systems are currently considered secondary treatment practices due to limited field performance data, although pollutant removal efficiency is anticipated to be similar to that of infiltration trenches and basins. Figure 11-S12-1 shows several examples of common underground infiltration systems.

Reasons for Limted Use

* Limited available monitoring data and undocumented field longevity.

* Potential failure due to improper siting, design (including adequate pretreatment), construction, and maintenance.

* Susceptible to clogging by sediment.

* Risk of groundwater contamination depending on subsurface conditions, land use, and aquifer susceptibility.

* Not suitable for stormwater runoff from land uses or activities with the potential for high sediment or pollutant loads.

Suitable Applications

* As an alternative to traditional infiltration trenches and basins for space-limited sites. These systems can be installed under parking lots and other developed areas, provided that the system can be accessed for maintenance purposes.

* Useful in stormwater retrofit applications or as part of a stormwater treatment train to provide additional groundwater recharge and storage volume to attenuate peak flows.

Design Considerations

The material of construction, configuration, and layout of underground infiltration systems vary considerably depending on the system manufacturer. Specific design criteria and specifications for these systems can be obtained from system manufacturers or vendors. General design elements common to most of these systems are summarized below. The reader should refer to the Infiltration Practices section of this chapter for additional information on siting, design, construction, and maintenance considerations.

* Siting: Underground infiltration systems are generally applicable to small development sites (typically less than 10 acres) and should be installed in locations that are easily accessible for routine and non-routine maintenance. These systems should not be located in areas or below structures that cannot be excavated in the event that the system needs to be replaced. Similar to infiltration trenches and basins, underground infiltration systems should only be used with soils having suitable infiltration capacity (as confirmed through field testing) and for land uses, activities, or areas that do not pose a risk of groundwater contamination.

* Pretreatment: Appropriate pretreatment (e.g., oil/particle separator, hydrodynamic device, catch basin inserts, or other secondary or primary treatment practices) should be provided to remove sediment, floatables, and oil and grease.

* Design Volume: Underground infiltration structures should be designed as off-line practices to infiltrate the entire water quality volume. A flow bypass structure should be located upgradient of the infiltration structure to convey high flows around the structure.

* Draining Time: Infiltration structures should be designed to completely drain the water quality volume into the soil within 48 hours after the storm event and completely dewater between storms. A minimum draining time of 6 hours is recommended to ensure adequate pollutant removal. Standing water for longer than 5 days can lead to potential mosquito-breeding problems. Potential mosquito entry points should be sealed (adult female mosquitoes can use openings as small as 1/16 inch to access water for egg laying).

* Infiltration Rate: The minimum acceptable field-measured soil infiltration rate is 0.3 inches per hour. Field-measured soil infiltration rates should not exceed 5.0 inches per hour. This generally restricts application to soils of NRCS Hydrologic Soil Group A. Some Group B soils may be suitable if field-measured infiltration rates exceed 0.3 inches per hour.