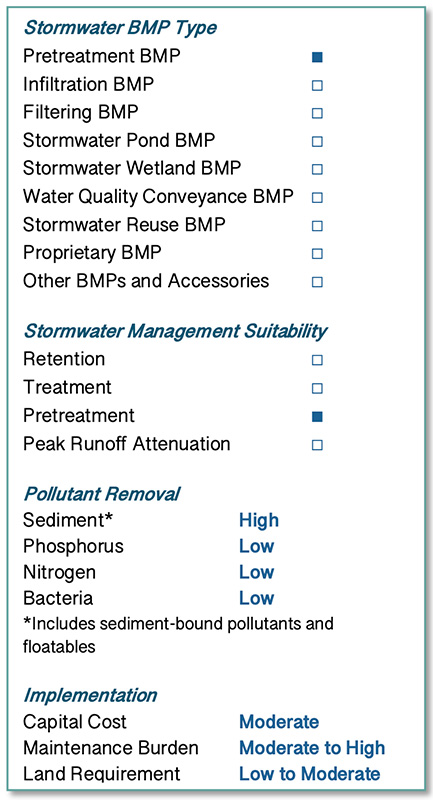

Oil grit separators are underground, multi-chambered systems designed to remove coarse sediment, debris, and floatables including trash and oil. Oil grit separators are typically designed as off-line systems for pretreatment of runoff from small impervious areas and bypass of larger flows. Due to their limited storage capacity and volume, these systems have only limited water quality treatment and peak flow attenuation capabilities.

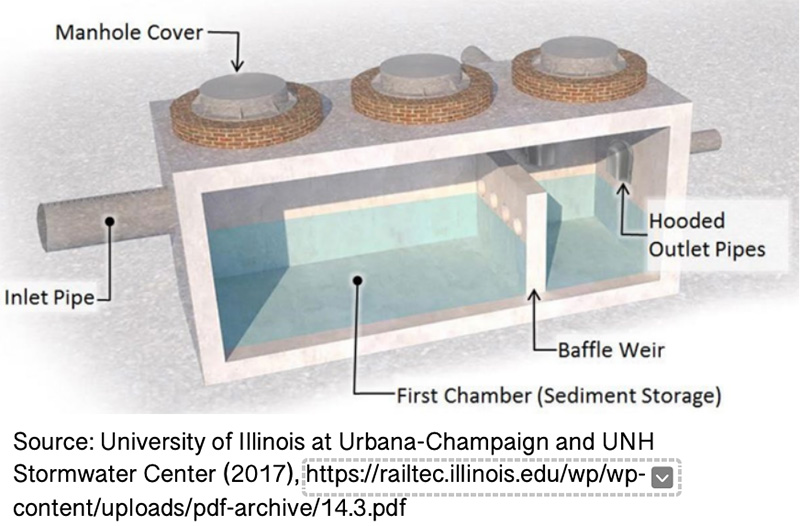

Oil grit separators typically consist of multiple baffled chambers and rely on gravity and the physical characteristics of oil and sediments to achieve pollutant removal. In a typical three-chamber system, the first chamber is a sedimentation chamber where floatable debris is trapped and gravity settling of sediments occurs, the second chamber is designed primarily for oil separation, and the third chamber provides additional settling prior to discharging to the storm drain system or downstream treatment practice. Many design modifications exist to enhance system performance including the addition of orifices, inverted elbow pipes, and diffusion structures. A two chambered system can be used to maximize sediment storage when the outlet pipes, in the second chamber, are fitted with hoods.

Single-chamber wastewater oil/water separators should not be used for stormwater applications because the single-chamber design does not provide sufficient protection against re-suspension of sediment during runoff events.

Proprietary separators and similar devices can be used as pretreatment. These are addressed in the Proprietary Pretreatment Device section of this Manual, as well as in Chapter 11 - Proprietary Stormwater BMPs.