Description

Permeable pavement is designed to allow rain and snowmelt to pass through it, thereby reducing runoff from a site, promoting groundwater recharge, and filtering some stormwater pollutants. Permeable paving materials are alternatives to conventional pavement surfaces and include:

* Modular concrete paving blocks

* Modular concrete or plastic lattice

* Cast-in-place concrete grids

* Soil enhancement technologies

* Other materials such as gravel, cobbles, wood,

mulch, brick, and natural stone.

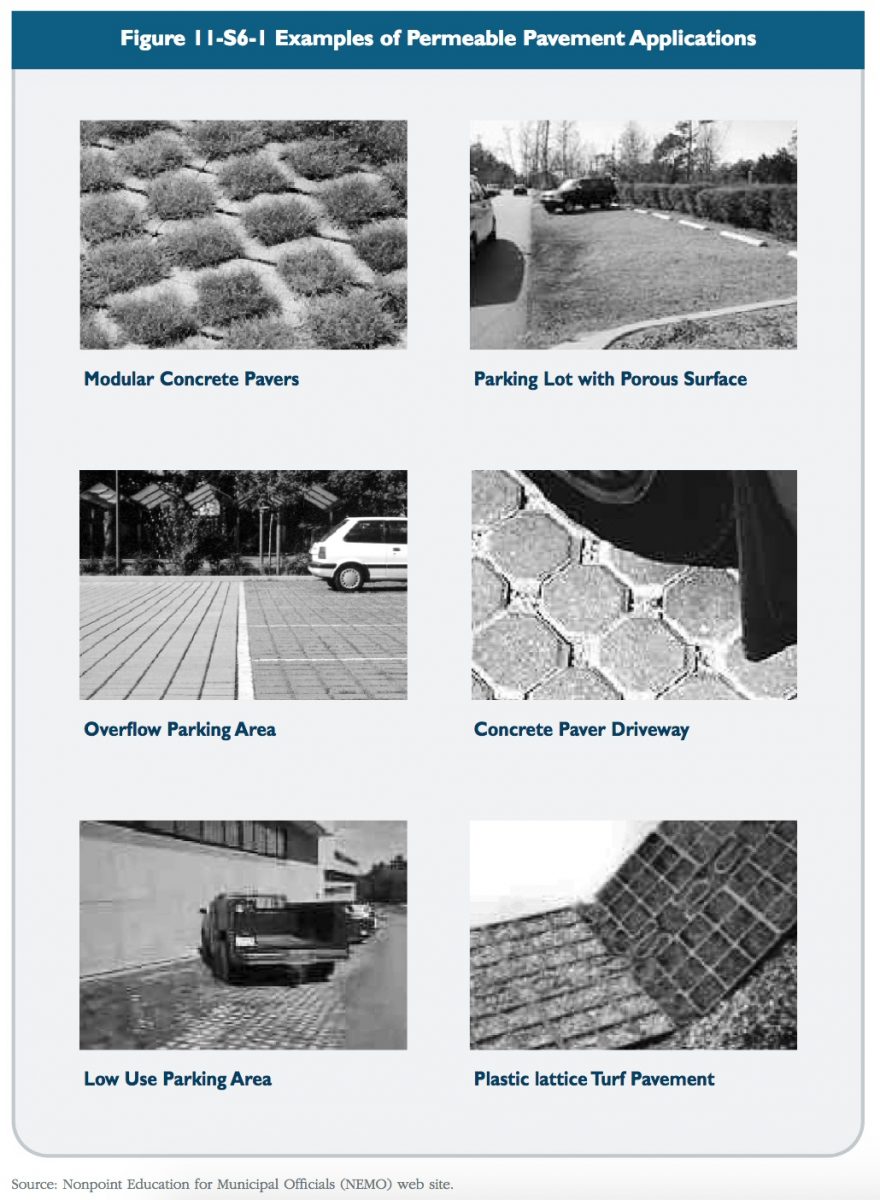

These practices increase a site’s load bearing capacity and allow grass growth and infiltration (Metropolitan Council, 2001). Modular paving blocks or grass pavers consist of interlocking concrete or plastic units with spaces planted with turf or gravel for infiltration. The pavers are typically placed in a sand bed and gravel sub-base to enhance infiltration and prevent settling. Modular paving systems also include plastic lattice that can be rolled, cut to size, and filled with gravel or turfgrass. Cast-in-place concrete pavement incorporates gaps filled with soil and grass and provides additional structural capacity. Soil enhancement technologies have also been developed in which a soil amendment such as synthetic mesh is blended with a permeable soil medium to create an engineered load-bearing root zone (Metropolitan Council, 2001). Other traditional materials with varying degrees of infiltration capacity such as gravel, cobbles, wood, mulch, and stone can be used for driveways, walking trails, and other similar low traffic surfaces. Figure 11-S6-1 illustrates examples of common permeable pavement applications.

Porous asphalt or concrete (i.e., porous pavement), which look similar to traditional pavement but are manufactured without fine materials and incorporate additional void spaces, are only recommended for certain limited applications in Connecticut due to their potential for clogging and high failure rate in cold climates. Porous pavement is only recommended for sites that meet the following criteria:

* Low traffic applications (generally 500 or fewer average daily trips or ADT).

* The underlying soils are sufficiently permeable (see Design Considerations below).

* Road sand is not applied.

* Runoff from adjacent areas is directed away from the porous pavement by grading the surrounding landscape away from the site or by installing trenches to collect the runoff.

* Regular maintenance is performed (sweeping, vacuum cleaning).

Reasons for Limited Use

* Not recommended in areas with high traffic volumes (generally greater than 500 ADT).

* Susceptible to clogging by sediment.

* Does not provide significant levels of pollutant removal. Some treatment is provided by the adsorption, filtration, and microbial decomposition at the base-subgrade interface (Schueler et al., 1992).

* Snow removal is difficult since plows may not be used, sand application can lead to premature clogging, and salt can result in groundwater contamination.

* Applicable to small drainage areas.

* Not applicable to low permeability soils or soils prone to frost action.

* Potential failure due to improper siting, design, construction, and maintenance.

* Risk of groundwater contamination depending on subsurface conditions, land use, and aquifer susceptibility. Should not be used in public drinking water aquifer recharge areas except in certain “clean” residential settings where measures are taken to protect groundwater quality.

* Not suitable for land uses or activities with the potential for high sediment or pollutant loads or in areas with subsurface contamination.

* May not be suitable for areas that require wheelchair access due to the pavement texture.

Suitable Applications

* In combination with alternative site design or Low Impact Development techniques to reduce stormwater runoff volumes and pollutant loads.

* Low traffic (generally 500 ADT or less) areas of parking lots (i.e., overflow parking for malls and arenas), driveways for residential and light commercial use, walkways, bike paths, and patios.

* Roadside right-of-ways and emergency access lanes.

* Useful in stormwater retrofit applications where space is limited and where additional runoff control is required.

* In areas where snow plowing is not required.

Design Considerations

Permeable pavement is a type of infiltration practice similar to the primary treatment infiltration practices described in previous sections of this chapter. Many of the siting, design, construction, and maintenance considerations for permeable pavement are similar to those of other infiltration practices. In addition, modular pavers and grids should be installed and maintained in accordance with the manufacturer’s instructions. General considerations for permeable pavement are summarized below:

* Soils: Permeable pavement should only be used with soils having suitable infiltration capacity as confirmed through field testing. Field-measured soil infiltration rates should be at least 0.3 inches per hour. Percolation should be complete within 48 hours (Pennsylvania Association of Conservation Districts et al., 1998). Field-measured soil infiltration rates should not exceed 5.0 inches per hour to allow for adequate pollutant attenuation in the soil. This generally restricts application to soils of NRCS Hydrologic Soil Group A. Some Group B soils may be suitable if field-measured infiltration rates exceed 0.3 inches per hour. Refer to the Infiltration Practices section of this chapter for recommended field measurement techniques. Permeable pavement should not be used on fill soils or soils prone to frost action.

* Land Use: Permeable pavement should not be used in public drinking water aquifer recharge areas or where there is a significant concern for groundwater contamination. Exceptions may include certain “clean” residential applications where measures are taken to protect groundwater quality (e.g., residential driveways or walkways graded to drain away from the permeable pavement). Permeable pavement is not appropriate for land uses where petroleum products, greases, or other chemicals will be used, stored, or transferred. Permeable paving materials should not be used in areas that receive significant amounts of sediment or areas that require sand and salt application for winter deicing.

* Slope: Permeable pavement should not be used in areas that are steeply sloped (>15%), such as steep driveways, as this may lead to erosion of the material in the voids.

* Water Table/Bedrock: The seasonally high water table or bedrock, as documented by on-site soil testing, should be at least 3 feet below grade. Permeable pavement should be located at least 100 feet from drinking water wells.

* Construction: Manufacturer’s guidelines should be followed for installation. Generally, the following procedures are followed for construction of modular pavement systems:

Site Preparation

* Site must be excavated and fine graded to the depth required by the base design.

* Roller pressure should be applied to compact soils.

* Base rock (3” to 6” of ¾” clean gravel) is then installed and compacted to approximately 95% of Standard Proctor Density.

* A 1” sand layer is placed on top of the gravel layer and compacted.

* The pavers are then installed according to manufacturer’s requirements.

Planting

* At least 1/8” to ¼” of the paver must remain above the soil to bear the traffic load.

* Sod or seeding method may be used.

* If sod is used, the depth of backfill required will depend on the depth of the sod. Sod is laid over the pavers, watered thoroughly, and then compressed into the cells of the pavers.

* If grass is planted from seed, the appropriate soil should be placed in the cells, tamped into the cells, and then watered thoroughly so that the appropriate amount of paver is exposed. The soil is then ready for planting with a durable grass seed.

* Traffic should be excluded from the area for at least a month to allow for establishment of grass.

* Operation and Maintenance: Permeable pavement is easiest to maintain in areas where access to the pavement is limited and controlled and where pavement maintenance can be incorporated into a routine site maintenance program such as commercial parking lots, office buildings, and institutional buildings (Pennsylvania Association of Conservation Districts et al., 1998). Turf pavers can be mowed, irrigated, and fertilized like other turf areas. However, fertilizers and other chemicals may adversely affect concrete products, and the use of such chemicals should be minimized. Pavers should be inspected once per year for deterioration and to determine if soil/vegetation loss has occurred. Soil or vegetation should be replaced or repaired as necessary. Care must be exercised when removing snow to avoid catching the snow plow on the edges of the pavers. Permeable pavement should be regularly cleared of tracked mud or sediment and leaves.

Plans for permeable pavement should identify detailed inspection and maintenance requirements, inspection and maintenance schedules, and those parties responsible for maintenance.

References

Metropolitan Council. 2001. Minnesota Urban Small Sites BMP Manual: Stormwater Best Management Practices for Cold Climates. Prepared by Barr Engineering Company. St. Paul, Minnesota.

Nonpoint Education for Municipal Officials (NEMO) website, URL: http://nemo.uconn.edu.

Pennsylvania Association of Conservation Districts, Keystone Chapter Soil and Water Conservation Society, Pennsylvania Department of Environmental Protection, and Natural Resources Conservation Service. 1998. Pennsylvania Handbook of Best Management Practices for Developing Areas. Prepared by CH2MHILL.

Schueler, T.R., Kumble, P.A., and M.A. Heraty. 1992. A Current Assessment of Urban Best Management Practices: Techniques for Reducing Non-Point Source Pollution in the Coastal Zone. Department of Environmental Programs. Metropolitan Washington Council of Governments.