Description

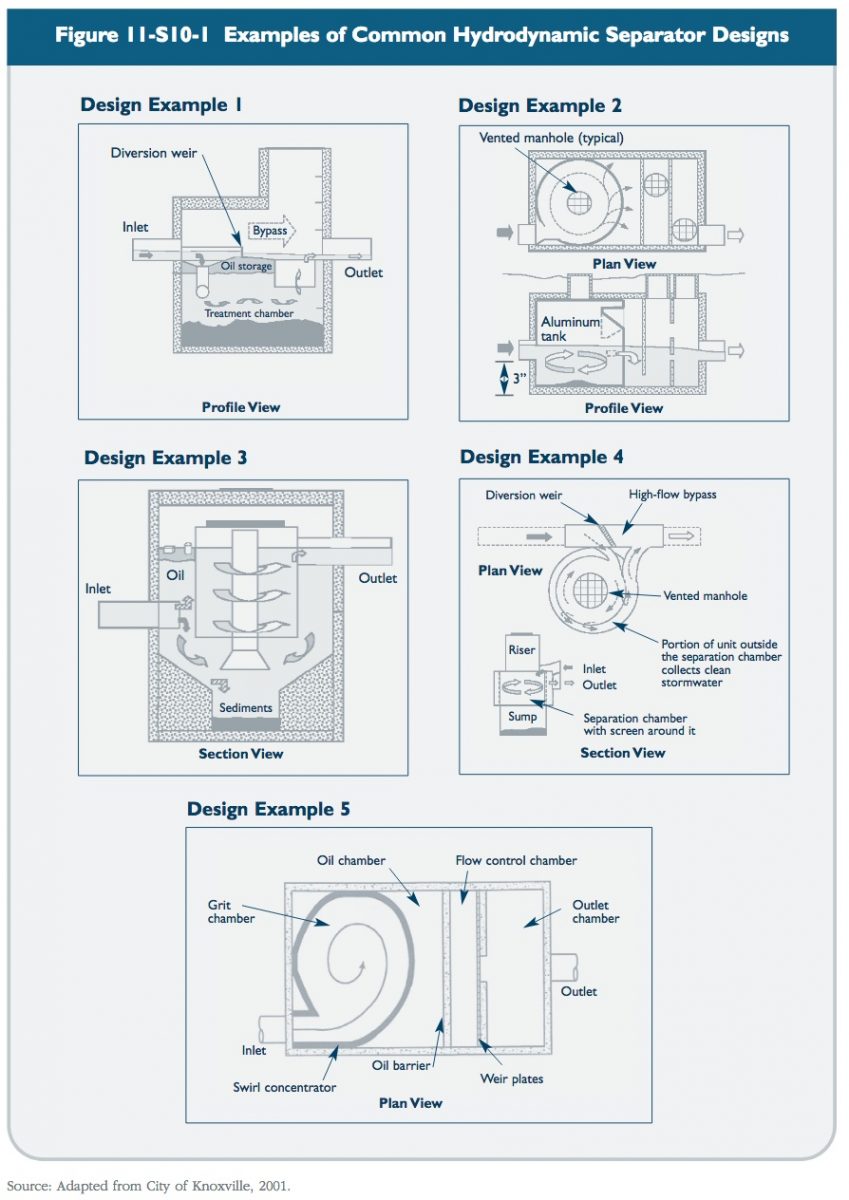

This group of stormwater treatment technologies includes a wide variety of proprietary devices that have been developed in recent years. These devices, also known as swirl concentrators, are modifications of traditional oil/particle separators that commonly rely on vortex-enhanced sedimentation for pollutant removal. They are designed to remove coarse solids and large oil droplets and consist primarily of cylindrical-shaped devices that are designed to fit in or adjacent to existing stormwater drainage systems (Washington, 2000). In these structures, stormwater enters as tangential inlet flow into the cylindrical structure. As the stormwater spirals through the chamber, the swirling motion causes the sediments to settle by gravity, removing them from the stormwater (EPA, 2002). Some devices also have compartments or chambers to trap oil and other floatables. Figure 11-S10-1 shows several examples of common hydrodynamic separator designs (no endorsement of any particular product is intended).

Although swirl concentration is the most common technology used in hydrodynamic separators, others use circular screening systems or engineered cylindrical sedimentation. Circular screened systems use a combination of screens, baffles, and inlet and outlet structures to remove debris, large particle total suspended solids, and large oil droplets. Structures using engineered cylindrical sedimentation use an arrangement of internal baffles and an oil and sediment storage compartment. Other proprietary technologies incorporate an internal high flow bypass with a baffle system in a rectangular structure to simulate plug

flow operation. When properly engineered and tested, these systems can also be an improvement over conventional oil/particle separators and offer removal efficiencies similar to swirl chamber technologies. Sorbents can also be added to these structures to increase removal efficiency (Washington, 2000).

Reasons for Limited Use

* Limited peer-reviewed performance data. Some independent studies suggest only moderate pollutant removal. (See Chapter Six for a description of the recommended evaluation criteria and protocols for consideration of these technologies as primary treatment practices.)

* Cannot effectively remove soluble pollutants or fine particles.

* Can become a source of pollutants due to re-suspension of sediment unless maintained regularly. Maintenance often neglected (“out of sight and out of mind”).

Suitable Applications

* Where higher sediment and pollutant removal efficiencies are required over a range of flow conditions, as compared to conventional oil/particle or oil/grit separators.

* For limited removal of trash, debris, oil and grease, and sediment from stormwater runoff from relatively small impervious areas with high traffic volumes or high potential for spills such as:

- Parking lots

- Streets

- Truck loading areas

- Gas stations

- Refueling areas

- Automotive repair facilities

- Fleet maintenance yards

- Commercial vehicle washing facilities

- Industrial facilities.

* To provide pretreatment for other stormwater treatment practices.

* For retrofit of existing stormwater drainage systems, particularly in highly developed (ultra-urban) areas where larger conventional treatment practices are not feasible or where aboveground treatment practices are not an option.

Design Considerations

Due to the proprietary nature of these products, hydrodynamic separators should be designed according to the manufacturer’s recommendations. Some general design considerations for these devices include:

* Drainage Area: The recommended maximum contributing drainage area to individual devices varies by manufacturer, model, etc.

* Sizing/Design: In most instances, hydrodynamic separators should be used in an off-line configuration to treat the design water quality flow (peak flow associated with the design water quality volume). Upstream diversion structures can be used to bypass higher flows around the device. Sizing based on flow rate allows these devices to provide treatment within a much smaller area than conventional volume-based stormwater treatment practices such as ponds, wetlands, and infiltration practices. Potential mosquito entry points should be sealed (adult female mosquitoes can use openings as small as 1/16 inch to access water for egg laying). Hydrodynamic separators should be used in conjunction with Cape Cod curbing or other similar curbing that allows amphibians to climb to avoid funneling amphibians into treatment chambers, where they are killed.

* Performance: Performance is dependent on many variables such as particle size, sediment concentration, water temperature, and flow rate. Hydrodynamic separators should be sized and compared based on performance testing of comparable size particles, influent concentrations, and testing protocols. Comparative performance testing that establishes a performance curve over the full operating range of the technology should be considered a prerequisite to any meaningful performance based sizing.

* Maintenance: Frequent inspection and cleanout is critical for proper operation of hydrodynamic separators. Structures that are not maintained can be significant sources of pollution. Recommended maintenance requirements and schedules vary with manufacturer, but in general these devices need to be cleaned quarterly. Typical maintenance includes removal of accumulated oil and grease, floatables, and sediment using a vacuum truck or other ordinary catch basin cleaning equipment.

Design plans for hydrodynamic separators should identify detailed inspection and maintenance requirements, inspection and maintenance schedules, and those parties responsible for maintenance.

* Sediment Disposal: Polluted water or sediment removed from these devices should be properly handled and disposed in accordance with local, state, and federal regulations. Before disposal, a detailed chemical analysis of the material should be performed to determine proper methods for storage and disposal.

References

City of Knoxville. 2001. Knoxville BMP Manual. City of Knoxville Engineering Department, Knoxville, Tennessee.

United States Environmental Protection Agency (EPA). 2002. National Menu of Best Management Practices for Stormwater Phase II.

URL: http://www.epa.gov/npdes/menuofbmps/menu.htm, Last Modified January 24, 2002.

Washington State Department of Ecology (Washington). 2000. Stormwater Management Manual for Western Washington, Final Draft. Olympia, Washington.