Description

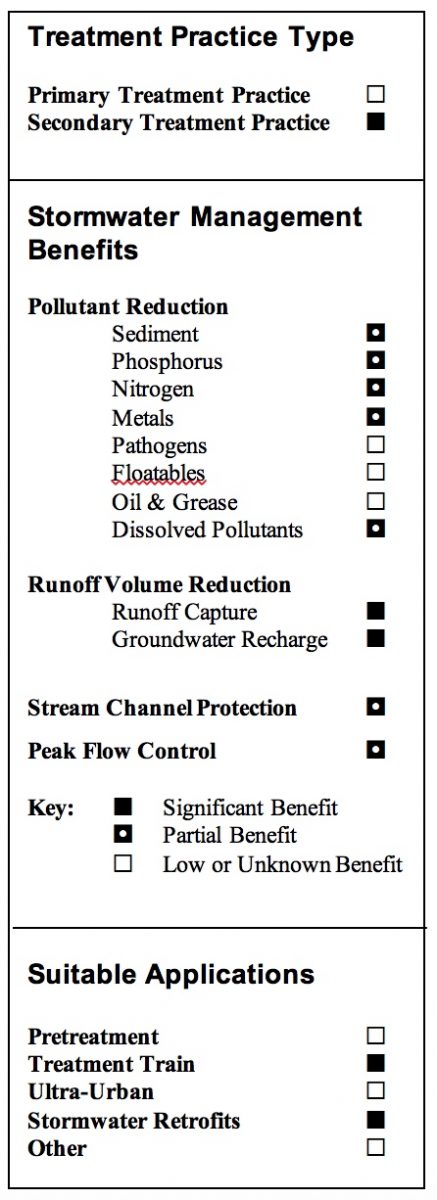

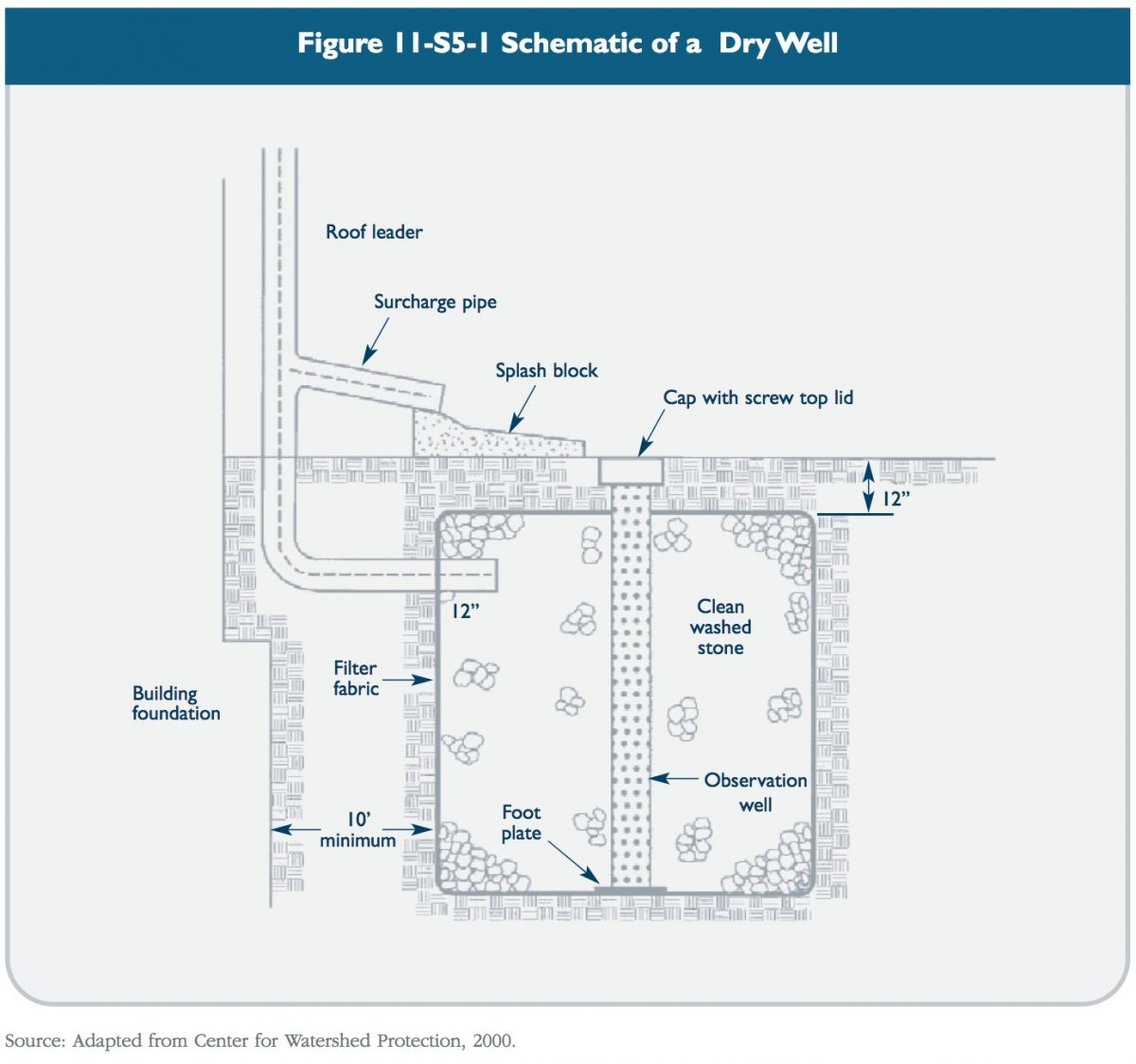

Dry wells are small excavated pits filled with aggregate, which receive clean stormwater runoff primarily from building rooftops. Dry wells function as infiltration systems to reduce the quantity of runoff from a site and recharge groundwater. Dry wells treat stormwater runoff through soil infiltration, adsorption, trapping, filtering, and bacterial degradation. The use of dry wells is applicable for small drainage areas with low sediment or pollutant loadings and where soils are sufficiently permeable to allow reasonable rates of infiltration. Figure 11-S5-1 shows a schematic of a typical dry well design. Figure 11-S5-2 depicts an alternative precast concrete dry well design.

Reasons for Limited Use

* Applicable to small drainage areas (one acre or

less).

* Potential failure due to improper siting, design,

construction, and maintenance.

* Susceptible to clogging by sediment.

* Risk of groundwater contamination depending on subsurface conditions, land use, and aquifer susceptibility.

* Not suitable for stormwater runoff from land uses or activities with the potential for high sediment or pollutant loads.

* Can drain wetlands or vernal pools if roof water is captured and released in another drainage area or below the wetland/vernal pool area.

Suitable Applications

* For infiltration of rooftop runoff that is unlikely to contribute significant loadings of sediment or pollutants (i.e., non-industrial, non-metallic roofs). Dry wells are not recommended for infiltrating parking lot runoff without pretreatment to remove sediment, hydrocarbons, and other pollutants.

* These systems can be installed under parking lots and other developed areas, provided that the system can be accessed for maintenance purposes.

* Useful in stormwater retrofit applications where space is limited and where additional runoff control is required.

* Where storm drains are not available and where adequate pretreatment is provided.

Design Considerations

Dry wells are small-scale infiltration systems similar to the primary treatment infiltration practices described in previous sections of this chapter. Many of the siting, design, construction, and maintenance considerations for dry wells are similar to those of infiltration trenches, which are summarized below.

* Soils: Dry wells should only be used with soils having suitable infiltration capacity (as confirmed through field testing). The minimum acceptable field-measured soil infiltration rate is 0.3 inches per hour. Field-measured soil infiltration rates should not exceed 5.0 inches per hour. This generally restricts application to soils of NRCS Hydrologic Soil Group A. Some Group B soils may be suitable if field-measured infiltration rates exceed 0.3 inches per hour. Refer to the Infiltration Practices section of this chapter for recommended field measurement techniques. One infiltration test and test pit or soil boring is recommended at the proposed location of the dry well. An observation well consisting of a well-anchored, vertical perforated PVC pipe with lockable aboveground cap should be installed to monitor system performance.

* Land Use: Dry wells should only be used to infiltrate relatively clean runoff such as rooftop runoff. Dry wells should not be used to infiltrate runoff containing significant solids concentrations or concentrations of soluble pollutants that could contaminate groundwater, without adequate pretreatment. Appropriate pretreatment (e.g., filter strip, oil/particle separator, hydrodynamic device, roof washer for cisterns and rain barrels, catch basin inserts, or other secondary or primary treatment practices) should be provided to remove sediment, floatables, and oil and grease.

* Drainage Area: The contributing drainage area to a dry well should be restricted to one acre or less.

* Water Table/Bedrock: The bottom of the dry well should be located at least 3 feet above the seasonally high water table or bedrock, as documented by on-site soil testing.

* Size/Depth: Dry wells should be designed to completely drain the water quality volume (or larger runoff volumes for additional groundwater recharge) into the soil within 48 hours after the storm event. Dry wells should completely dewater between storms. A minimum draining time of 6 to 12 hours is recommended to ensure adequate pollutant removal. Dry wells should be equipped with overflows to handle larger runoff volumes or flows.

* Miscellaneous: Dry wells should not be placed over fill materials, should be located a minimum of 10 feet from building foundations, and should be located at least 100 feet away from:

- Drinking water supply wells

- Septic systems (any components)

- Surface water bodies.

- Building foundations (at least 100 feet upgradient and at least 25 feet downgradient from building foundations).

* Construction: Refer to the Infiltration Practices section of this chapter for construction recommendations. The dry well should be filled with 1.5 to 3.0-inch diameter clean washed stone and be wrapped with filter fabric. The dry well should be covered by a minimum of 12 inches of soil.

* Operation and Maintenance: Refer to the Infiltration Practices section of this chapter for operation and maintenance recommendations.

Plans for dry wells should identify detailed inspection and maintenance requirements, inspection and maintenance schedules, and those parties responsible for maintenance.

References

Center for Watershed Protection (CWP). 2000. The Vermont Stormwater Management Handbook Technical Support Document – Public Review Draft. Prepared For Vermont Agency of Natural Resources.

United States Environmental Protection Agency (EPA). 2002. National Menu of Best Management Practices for Stormwater Phase II.

URL: http://www.epa.gov/npdes/menuofbmps/menu.htm, Last Modified January 24, 2002.