Description

Alum injection is the addition of aluminum sulfate (alum) solution to stormwater before discharging to a receiving water body or stormwater treatment practice. When alum is injected into stormwater it binds with suspended solids, metals, and phosphorus and forms aluminum phosphate and aluminum hydroxide precipitates. These precipitates settle out of the water column and are deposited in the bottom sediments in a stable, inactive state (referred to as “floc”).

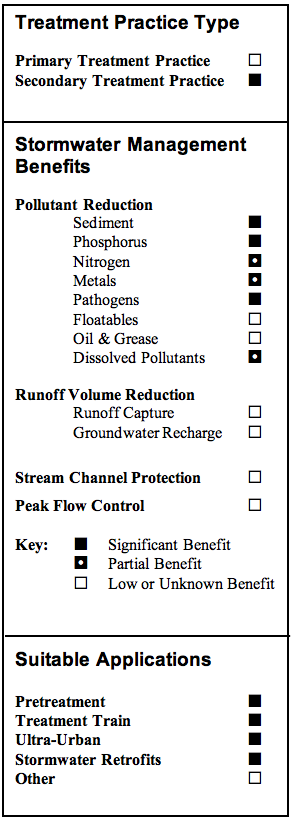

The injection of liquid alum into storm sewers has been used to reduce the water quality impacts of stormwater runoff to lakes and other receiving water bodies, particularly to reduce high phosphorus levels and address eutrophic conditions (EPA, 2002). Alum injection systems are commonly used in some parts of the country as stormwater retrofits for existing discharges to lakes and ponds, but may also be used as pretreatment for stormwater ponds and other treatment practices (ASCE, 2001). Alum addition should be considered only after all other best management practices have been implemented.

Alum injection is the addition of aluminum sulfate (alum) solution to stormwater before discharging to a receiving water body or stormwater treatment practice. When alum is injected into stormwater it binds with suspended solids, metals, and phosphorus and forms aluminum phosphate and aluminum hydroxide precipitates. These precipitates settle out of the water column and are deposited in the bottom sediments in a stable, inactive state (referred to as “floc”).

The injection of liquid alum into storm sewers has been used to reduce the water quality impacts of stormwater runoff to lakes and other receiving water bodies, particularly to reduce high phosphorus levels and address eutrophic conditions (EPA, 2002). Alum injection systems are commonly used in some parts of the country as stormwater retrofits for existing discharges to lakes and ponds, but may also be used as pretreatment for stormwater ponds and other treatment practices (ASCE, 2001). Alum addition should be considered only after all other best management practices have been implemented.

Reasons for Limited Use

• Limited long-term performance data.

• Requires ongoing operation unlike most other stormwater treatment practices.

• Improper dosing of chemicals may have negative impacts on downstream water bodies.

• Increased the volume of sediment/floc (and associated pollutant concentrations) that must be disposed of.

• Typically not cost effective for drainage areas less than 50 acres.

• Alum application may be approved as part of a state stormwater permit or could require an individual state permit. The DEP Water Management Bureau should be contacted for further permit guidance.

Suitable Applications

• Best suited to situations where a large volume of water is stored in one area.

• As part of a stormwater treatment train or pretreatment step to further reduce turbidity and fine suspended solids.

• For existing stormwater discharges to existing ponds and lakes, particularly in highly developed areas, where new stormwater treatment practices or other treatment options are not feasible.

Design Considerations

- Design: Alum injection systems typically consist of a flow-weighted dosing system designed to fit inside a storm sewer manhole, remotely located alum storage tanks, and a downstream pond or treatment practice that allows alum and pollutants to settle out (EPA, 2002). Alum dosage rates generally range between 5 and 10 milligrams per liter of alum solution and are determined on a flow-weighted basis during storm events. Lime is often added to raise the pH (between 8 and 11) and enhance pollutant settling. Jar testing is recommended to determine alum dosing rates and the need for pH control. Injection points in the storm drainage system should be approximately 100 feet upstream of the discharge point (ASCE, 2001). In addition to the settling pond, a separate floc collection pump-out facility is recommended to reduce the chance of resuspension and transport of floc to receiving waters by pumping floc to the sanitary sewer or onto nearby upland areas (with appropriate local, state, and federal regulatory approval, as necessary).

- Operation and Maintenance: Typical operation and maintenance requirements for alum injection systems include maintenance of pump equipment, power, chemical replacement, routine inspections, and equipment replacement (doser and pump-out facility). A trained operator should be on-site to adjust the chemical dosage and regulate flows, if necessary. Alum injection systems also require continued monitoring of water quality to detect potential negative impacts to receiving waters. The settling basin or pond should be dredged periodically to dispose of accumulated floc.

- Cost Considerations: Alum injection is a relatively expensive and labor-intensive treatment practice. Construction costs depend on watershed size and the number of outfalls treated, but construction costs generally range from $135,000 to $400,000. Due to the high construction cost, alum injection is not cost effective for drainage areas less than 50 acres. Operation and maintenance costs can vary from $6,500 to $50,000 per year depending on the size of the system (Harper and Herr, 1996).

Suitable Applications

• Best suited to situations where a large volume of water is stored in one area.

• As part of a stormwater treatment train or pretreatment step to further reduce turbidity and fine suspended solids.

• For existing stormwater discharges to existing ponds and lakes, particularly in highly developed areas, where new stormwater treatment practices or other treatment options are not feasible.